What Components and Modules Does a Capacitor Cost?

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. They are essential in a wide range of applications, from consumer electronics to industrial machinery. Understanding the cost factors associated with capacitors is vital for both consumers and manufacturers, as it influences purchasing decisions and product design. This blog post will explore the various components and modules that contribute to the cost of capacitors, providing insights into their functionality, manufacturing processes, and market dynamics.

II. Understanding Capacitors

A. Basic Principles of Capacitors

Capacitors are passive electronic components that store electrical energy in an electric field. They consist of two conductive plates separated by a dielectric material. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. The amount of energy a capacitor can store is determined by its capacitance, which is measured in farads (F).

B. Types of Capacitors

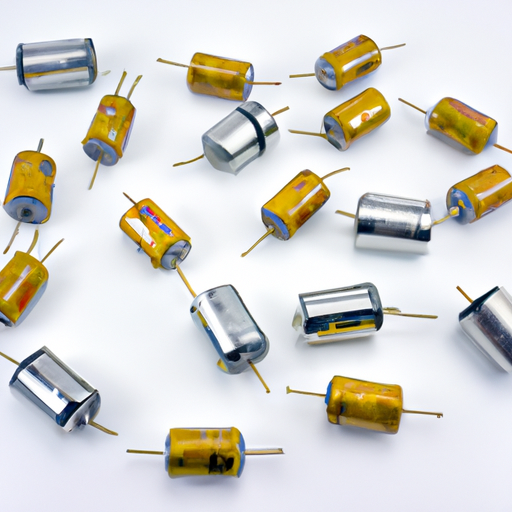

There are several types of capacitors, each with unique characteristics and applications:

1. **Ceramic Capacitors**: Known for their small size and reliability, ceramic capacitors are widely used in high-frequency applications.

2. **Electrolytic Capacitors**: These capacitors offer high capacitance values and are commonly used in power supply circuits.

3. **Tantalum Capacitors**: Tantalum capacitors are known for their stability and reliability, making them suitable for critical applications.

4. **Film Capacitors**: These capacitors are used in applications requiring high voltage and low loss, such as audio equipment.

C. Applications of Capacitors in Various Industries

Capacitors find applications across multiple industries:

1. **Consumer Electronics**: Used in smartphones, televisions, and computers for energy storage and signal filtering.

2. **Automotive**: Essential for power management and noise filtering in modern vehicles.

3. **Industrial Machinery**: Employed in motor drives and power supply systems to improve efficiency.

4. **Renewable Energy Systems**: Used in solar inverters and wind turbines for energy storage and management.

III. Components of a Capacitor

A. Dielectric Material

The dielectric material is a critical component of a capacitor, influencing its performance and cost. Common dielectric materials include:

1. **Ceramic**: Offers high stability and low losses, suitable for high-frequency applications.

2. **Electrolytic**: Provides high capacitance but is limited to specific applications due to polarity.

3. **Tantalum**: Known for its reliability and stability, often used in military and aerospace applications.

4. **Film**: Offers low losses and high voltage ratings, ideal for audio and high-frequency applications.

The choice of dielectric material affects not only the performance but also the cost of the capacitor. For instance, tantalum capacitors tend to be more expensive due to the cost of tantalum metal.

B. Conductive Plates

The conductive plates of a capacitor are typically made from materials such as aluminum or tantalum. The choice of material impacts both the capacitance and pricing:

1. **Aluminum**: Commonly used in electrolytic capacitors, aluminum plates are cost-effective but may have lower performance in high-frequency applications.

2. **Tantalum**: Used in tantalum capacitors, these plates offer high reliability but come at a premium price.

The thickness and surface area of the plates also play a role in determining the capacitance and overall cost of the capacitor.

C. Terminals and Leads

Capacitors come with various types of terminals and leads, which can affect their cost:

1. **Through-Hole**: These capacitors have leads that pass through the circuit board, typically used in larger applications.

2. **Surface Mount**: These capacitors are designed for compact applications and are soldered directly onto the surface of the circuit board.

The choice of terminal design can influence manufacturing costs, as surface mount technology often requires more advanced equipment.

IV. Manufacturing Processes

A. Overview of Capacitor Manufacturing

The manufacturing process of capacitors involves several steps, including:

1. **Material Preparation**: Sourcing and preparing dielectric materials and conductive plates.

2. **Assembly**: Layering the dielectric material between the conductive plates and attaching terminals.

3. **Encapsulation**: Protecting the capacitor with a casing to ensure durability and reliability.

4. **Testing**: Conducting quality control measures to ensure performance standards are met.

B. Cost Factors in Manufacturing

Several cost factors influence the manufacturing of capacitors:

1. **Raw Material Costs**: The prices of dielectric materials and conductive metals can fluctuate, impacting overall costs.

2. **Labor and Overhead Expenses**: Labor costs vary by region and can significantly affect manufacturing expenses.

3. **Equipment and Technology Investments**: Advanced manufacturing technologies can improve efficiency but may require substantial initial investments.

V. Market Dynamics

A. Supply and Demand Factors

The global market for capacitors is influenced by supply and demand dynamics:

1. **Global Market Trends**: The increasing demand for electronic devices drives the need for capacitors, leading to fluctuations in pricing.

2. **Impact of Technological Advancements**: Innovations in capacitor technology can create new markets and applications, affecting supply and demand.

B. Pricing Strategies of Manufacturers

Manufacturers employ various pricing strategies that can impact capacitor costs:

1. **Bulk Purchasing vs. Retail Pricing**: Buying capacitors in bulk often results in lower per-unit costs, while retail pricing can be significantly higher.

2. **Brand Reputation**: Established brands may charge a premium for their products due to perceived quality and reliability.

VI. Cost Breakdown of Capacitors

A. Average Costs of Different Types of Capacitors

The cost of capacitors varies widely based on type and application:

1. **Low-End Capacitors**: Ceramic capacitors can cost as little as a few cents, making them accessible for mass production.

2. **High-End Capacitors**: Tantalum and film capacitors can range from several dollars to tens of dollars, depending on specifications.

B. Additional Costs Associated with Capacitors

In addition to the base price, several additional costs may apply:

1. **Shipping and Handling**: Transportation costs can add to the overall expense, especially for international shipments.

2. **Import Tariffs and Taxes**: Depending on the region, tariffs and taxes can significantly impact the final cost of capacitors.

3. **Warranty and Support Services**: Manufacturers may offer warranties and support services, which can also affect pricing.

VII. Future Trends in Capacitor Technology

A. Innovations in Capacitor Design and Materials

The capacitor industry is witnessing innovations in design and materials, leading to improved performance and reduced costs. Developments in nanotechnology and new dielectric materials are paving the way for smaller, more efficient capacitors.

B. Potential Impact on Costs and Market Availability

As technology advances, the cost of producing high-performance capacitors may decrease, making them more accessible to a broader range of applications. This could lead to increased competition and lower prices in the market.

C. Sustainability Considerations in Capacitor Production

Sustainability is becoming a critical consideration in capacitor production. Manufacturers are exploring eco-friendly materials and processes to reduce environmental impact, which may influence costs and market dynamics in the future.

VIII. Conclusion

In summary, understanding the components and cost factors associated with capacitors is essential for consumers and manufacturers alike. From the choice of dielectric materials to the manufacturing processes and market dynamics, each element plays a role in determining the final price of capacitors. As technology continues to evolve, the future of capacitors looks promising, with innovations that may lead to improved performance and reduced costs. By staying informed about these trends, stakeholders can make better decisions in the ever-evolving landscape of electronics.

IX. References

1. Academic journals and articles on capacitor technology and applications.

2. Industry reports and market analysis from reputable sources.

3. Manufacturer websites and product catalogs for specific capacitor types and pricing information.