Information

dict2_description

Latest capacitor current specifications

2025-02-05

1

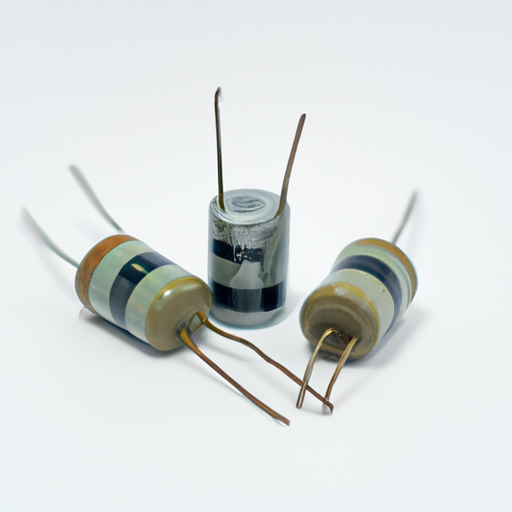

What are the popular capacitor product types?

2025-01-18

1

What are the product standards for capacitors?

2025-01-17

2

dict3_title

dict3_description